Mission statement

Leak-free solutions

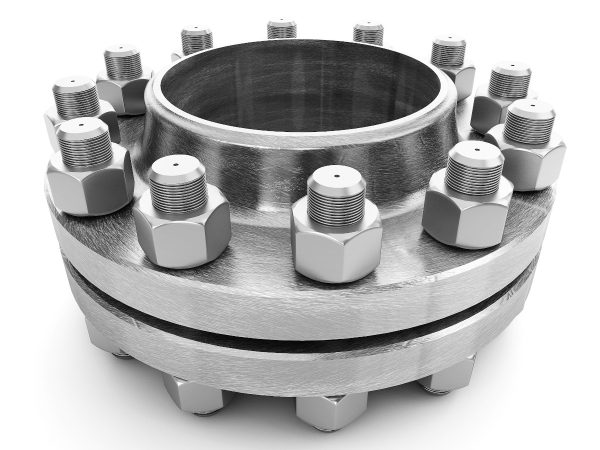

A flange connection or flange joint is a complex mechanical system and therefore the design that provides leak free solutions is the result of many decisions made/activities performed within a relatively narrow band of acceptable limits. Any flange calculation generated by our Flange Management Software is subject to appropriate review by qualified engineers.

Flange assembly requires knowledge and expertise. Determining how to assemble the flange connection requires knowledge of all the parts of a flange connection such as materials, forces and stresses, temperature effects and many other factors.

One of the activities essential to leak-free performance is the joint assembly process. The required guidelines must cover the assembly elements that are essential for a high level of joint integrity.

General

Plant owners are under increasing pressure to reduce fugitive emissions for a number of reasons, including environmental (legislation), safety and commercial (plant efficiency). A number of the resulting costs are often difficult to quantify, such as loss of product, cost of labour/materials to repair leaks, cost of cleaning the affected area, environmental fines and image. Flange Management offers the total package of services that provides the best possible chance of achieving a leak-free start-up.

Correct assembly of a critical flange joint requires calculation of the joint and determination of the correct bolt preload, lubricant and allowable alignment tolerances to seal the joint. It requires installation of the most appropriate gasket for the application, inspection of the flange face condition and bolt and nut condition, and controlled application of the determined bolt preload. Incorrect bolt loads, flange distortion, inappropriate gasket selection and uncontrolled flange assembly/bolt tightening methods are the main causes of joint leakage. By taking a few simple steps, these potential causes of failure can be eliminated.

Joint integrity

The integrity of flanged joints is often poorly understood by the asset owner. Mechanical failure of design (parts) or materials in general is the second most common cause of flanged joint failures. In general, fugitive emissions occur as a result of improperly calculated and sealed flange connections. Fugitive emissions are emissions of gases or vapours from pressurised equipment due to leaks and other unintended or irregular releases of gases, mostly from industrial activities.

Phases

In the design phase, the customer specifies the requirements for the flange connections. During the construction phase, the flange connections are checked by the contractor through inspections and various tests. To ensure adequate safety, these flange connections must also be maintained and inspected during the live phase. Based on the above, it is important that attention is paid to flange connections. Flange Management helps asset owners to get their flange calculations.

Legal frame of reference

The law requires an asset owner to take all reasonable steps to prevent spills and their consequences (duty of care).

Standardization

Standards such as ASME and EN provide an asset owner with guidance on how to deal with condition monitoring of flange connections during the management or operation of the pipeline system.

Our aim

Our aim is to make asset owners aware of the presence and specific risks of flanged joints in their pipeline system and how they can carry out systematic checks in the live phase. It also helps to improve asset owners’ awareness of high-risk issues in terms of (external) safety and therefore compliance with the national legislation.

Delineation

Flanged joints require special technical investigation. When we flange calculations, the following will be checked: Environmental management systems (requirements with guidelines for use) or own company guidelines for flanged connections that the asset owner can use to comply with the national legislation. The use of a method such as the PDCA cycle for pipeline flange connections in the management phase. The risk management system (RMS) must be based on the PDCA cycle methodology. This must be coherent, controlled and guaranteed.

Target group

Flange Management is intended for asset owners. The findings and recommendations provide an indicative view of the working method.